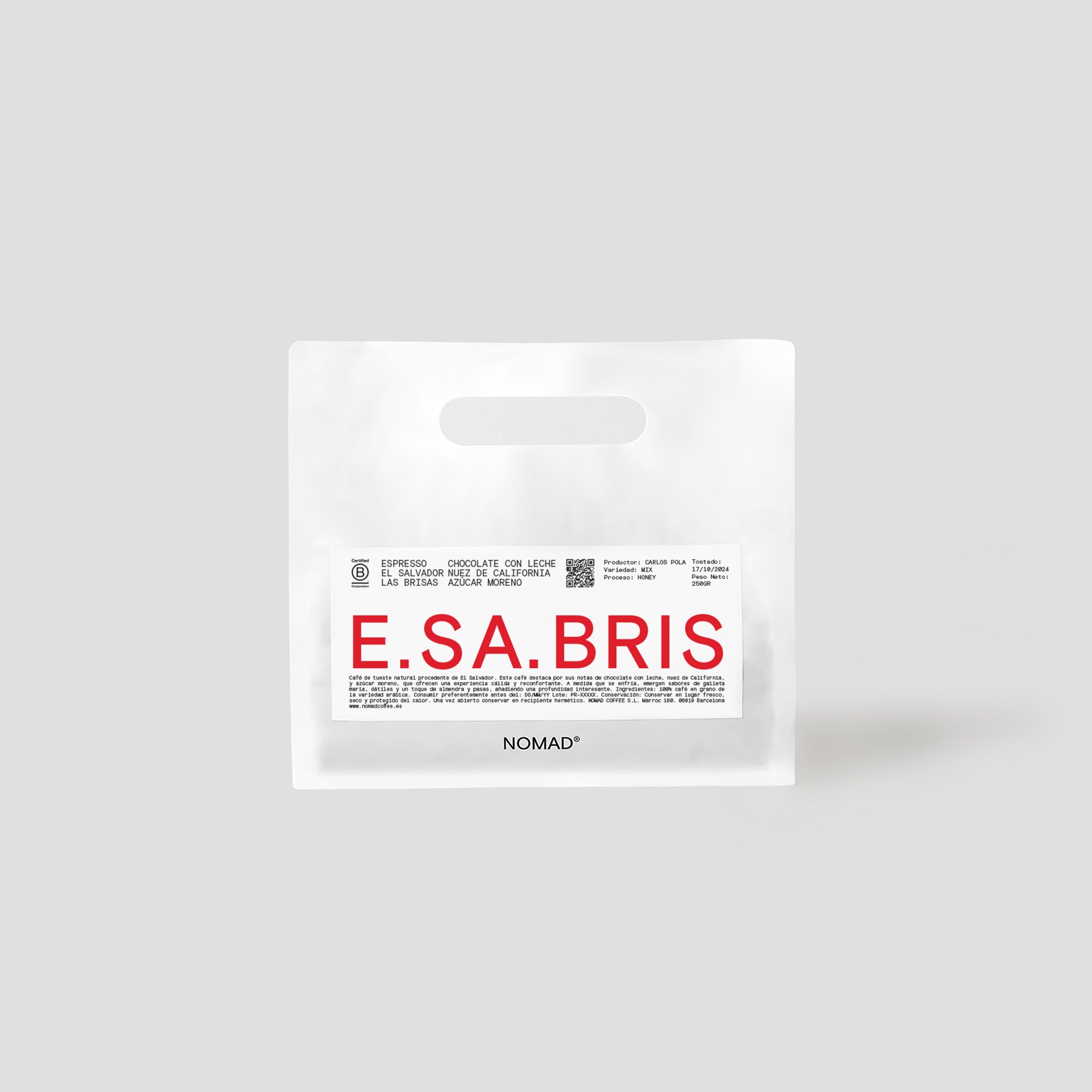

This coffee stands out for its notes of milk chocolate, California walnut, and brown sugar, which offer a warm and comforting experience. As it cools, flavors of maria cookie, dates, and a hint of almond and raisin emerge, adding interesting depth.

Finca Las Brisas, located in Juayúa, in the Apaneca Ilamatepec mountain range, is a clear example of how technology and sustainable agricultural practices can transform the future of coffee. While many producers in El Salvador have faced challenges such as climate change and rust, Carlos Pola has managed to maintain a healthy plantation with outstanding quality and increasing production.

Carlos, the fifth generation of a farming family, worked in the textile industry for 20 years before dedicating himself entirely to coffee in 2012, convinced that the specialty industry brought with it new opportunities. Today, he manages Finca Las Brisas and two other family farms, where he has invested in technology and sustainability to boost production.

One of his key innovations is the use of mycorrhizal fungi, which form a symbiotic relationship with the coffee trees, improving nutrient absorption and water retention, which has allowed him to keep his trees healthy even in times of drought.

Renovation of the Farm

When rust severely affected the region in 2012-2013, Carlos renovated most of his farm with disease-resistant varieties, keeping only a small percentage of Bourbon. Today, Finca Las Brisas grows a mix of hybrids, including Pacamara, Pacas and others, ensuring cup quality and sustainability.

21st Century Agriculture

Carlos has also implemented innovative techniques, such as contour farming, which helps conserve water and prevent erosion, and the use of technology to track coffee from the farm to the cup through QR codes. This avant-garde mentality has allowed the company to continue experimenting with new processing methods, always seeking to offer unique experiences to roasters.

This is our fourth consecutive year working with Carlos Pola and his team, and this is the second year with 100% direct contact, which further strengthens our collaboration and guarantees a coffee of the highest quality and traceability.

Process

The skin and pulp are removed from the coffee, leaving part or all of the mucilage (honey) of the coffee. The coffee is then floated and placed in sacks for 2 days in the shade to dehydrate. Pulping is done without water, followed by drying on raised beds. The first 2 days are dried in the sun, and then the process continues in the shade under saran. Some additional batches are dried on mud brick patios.

Remember that all our espresso roasted coffees can be prepared in your Moka Pot at home with the recipe that you will find in the NOMAD at Home section.

When replicating the recipe, there are different variables that can interfere in the final result of your cup, such as the roasting date, conservation of the beans, environment, water, state of the machines, etc. It is important to keep in mind that all these factors can influence and you may have to make small adjustments when replicating this recipe.

Recipe

18 gr dry

38 gr in liquid

29 seconds

Machine: Sage Barista Pro

Number of grinds: 16

Grinding time: 14s

Recommended mineral water: Lanjarón

TDS and percentage of extraction: 9.83 / 21.84 %.